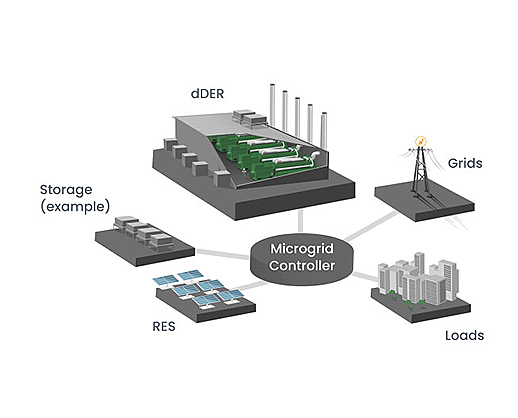

Microgrids are decentralized power systems containing loads and distributed energy resources (such as distributed generators, storage devices, or controllable loads) that can be operated in a controlled, coordinated way either while connected to the main power network or while islanded.

Microgrids are located within a clearly defined electrical boundary and may also include thermal loads and resources.

What is microgrid?

Microgrids are small-scale power generation and distribution systems containing loads, including thermal loads, and DERs such as distributed engines, renewable energy sources, and storage systems.

- They can operate as an isolated system or with clearly defined physical and electrical boundaries when connected to the main grid.

- Their size typically ranges between 0.1 and 10 MW, although they can be larger in industrial and commercial applications.

- In the past, microgrids predominantly were used for grid access and backup power. Now and in the future, they are more focused on resilience and sustainable/economical alternatives to the public grid.

Typical microgrid scope

A typical microgrid scope has a dispatchable distributed energy resource (dDER), another energy resource such as a solar PV, and a storage system such as a battery energy storage system (BESS).

- need to improve the reliability of power supply or;

- desire to get away from expensive centralized energy sources, especially during peak consumption hours or;

- need to reduce the carbon footprint produced by the company / community through use of cogeneration as a more efficient way of generating energy compared to centralized sources or;

- possibility of combining traditional local cogeneration using gaseous fuels with renewable energy sources (e.g. hydrogen, biogas, fuel cells, sun, wind, etc.).

When reliable power supply is key

Gas engine solutions are especially relevant if your microgrid supplies energy where uninterrupted power is critical (for example – hospitals, data centers, process industries, etc.).

Jenbacher gas engines ramp up to full power output in just a few minutes, providing your microgrid with necessary power, when it is needed.

At the same time, Jenbacher gas engines can be more environmentally friendly than diesel engines, due to generally lower emissions. That´s why gas engines are often used in microgrids with CHP solutions due to increasing environmental requirements. Jenbacher solutions offer fuel flexibility with engine versions that can handle different gas qualities. Also, they are suitable for high ambient temperatures and elevations.

Optimize your energy expenses wisely

Many grid clusters on the North American continent have dynamic electricity price levels, and of course there are certain seasons of the year and hours of the day when the cost of centralized energy peaks. In many cases, these spikes seriously increase the operating costs for microgrid consumers.

*Based on IEA ’16 electricity generation data for the EU-28 and EIA ’17 reference for average power plant heat factor.

Optimize your energy expenses wisely

The use of power generation with natural gas, and especially usage of gas engines in microgrids, allows stabilizing and better prediction for energy-related costs.Jenbacher takes the environmental agenda very seriously and we have a lot to offer to like-minded companies:

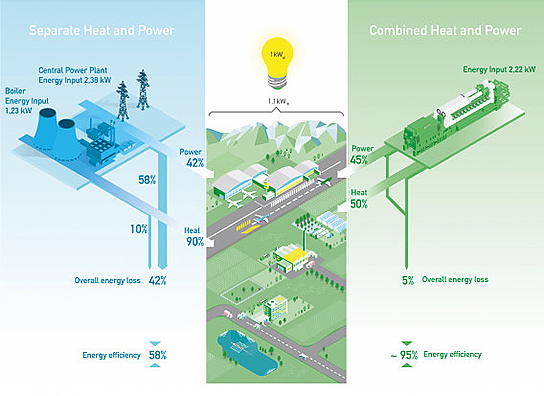

- COGENERATION. Our gas engines work efficiently in Cogeneration schemes. Cogeneration, or CHP, is simultaneous production of heat and power (in addition to efficient electricity production, Jenbacher CHP systems convert the waste heat created during an engine’s operation into useful hot-water or steam). It is usually more efficient compared to separate production at electrical power plants and boiler houses. Cogeneration solutions based on Jenbacher engines work with a total efficiency of up to 90% and more, maximizing conversion of gas energy into useful power. As a result, it helps your microgrid with CHP solution to be more efficient and decrease your carbon footprint.

- TRIGENERATION. Depending on your needs, you might want to consider using combined cooling, heat, and power (CCHP) systems, also called trigeneration systems. Such system is a combination of cogeneration plant and absorption chillers. Jenbacher engines offer an efficient solution for generating air conditioning and/or refrigeration. Cogeneration equipment offers high efficiency and low emissions. Absorption chillers provide an economic and environmental alternative to conventional refrigeration with compression chillers. Combining those two elements enables excellent total fuel efficiency, elimination of HCFC/CFC refrigerants, and reduces overall air emissions.

- GREEN GASES. Our engines do not only run efficiently on natural gas. They also work with biogas, landfill gas, wastewater gas, industrial syngas and other gases, converting greenhouse gases into useful energy and helping customers to achieve their environmental targets.

- HYDROGEN. Jenbacher is Ready for H2 – having launched the first hydrogen-powered engine years ago. Our gas engines can run on a mixture of gas and hydrogen as well as on pure hydrogen. Most of the already installed engines, which run on natural and other gases, can be converted to run on a hydrogen.

Flexible and scalable integrated solutions

Jenbacher can work on new microgrid projects or projects dedicated to modernizing existing microgrids.

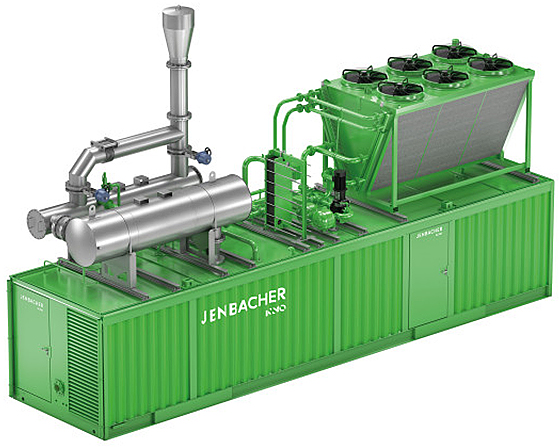

Flexibility is the key for integration purposes. Therefore, Jenbacher solutions can be supplied as modules for installation inside a building or as integrated solutions: containerized power generation or cogeneration/trigeneration solutions.

Jenbacher containers are available for Type 2, 3, 4 and 6 engines. Based on the expertise gained in several decades with over 3,000 containerized units delivered, our genset containers offer optimal performance in various site conditions. By applying the same high-quality standards to the complete package as to the engine, our containerized solutions ensure excellent reliability for your power and heat generation needs.

Jenbacher containerized solutions offer a variety of benefits to our customers, thanks to distinctive product features:

Product features

- Pre-installed package complete with auxiliary systems

- Compact footprint

- All components perfectly matched and tuned to the specific site requirements

Customer benefits

- Quick and easy site installation; less installation work to coordinate on site

- Less space consumed on site

- Optimal genset performance ensured by OEM

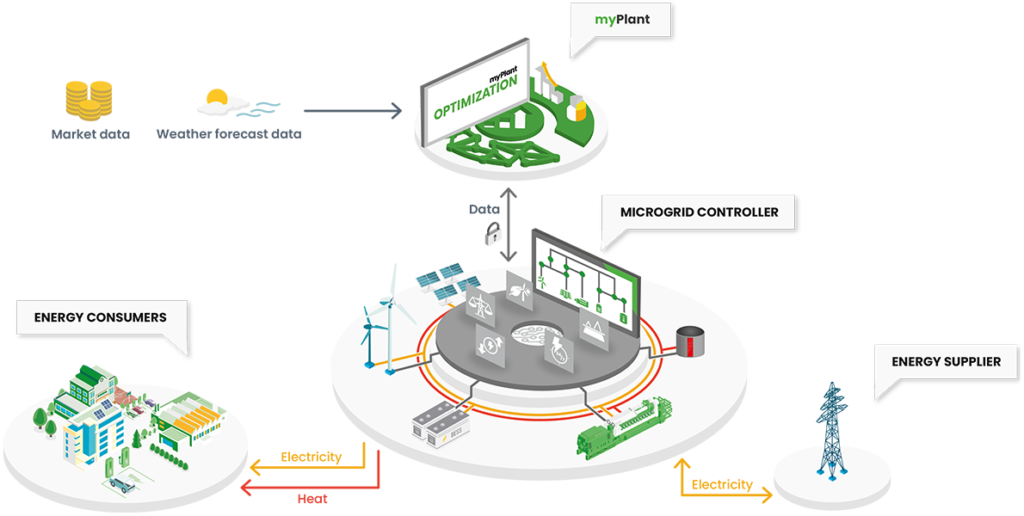

myPlant Optimization

We further improve economics and optimize energy management by connecting the microgrid to the optional myPlant Optimization offering. This artificial intelligence (AI)-based solution takes a holistic approach, improving the operational efficiency of your entire plant portfolio—from engine and heat pump to heat storage and the photovoltaic system – while taking opera-tional requirements and annual targets into account.

INNIO Cogeneration solutions are used by our customers across the globe, powering applications in variety of economic segments, for example – industrial manufacturing, commercial, municipal applications, greenhouses and many more.

Microgrids advantages

- Renewable integration

- Peak shaving

- Energy arbitrage

- Power reliability/islanding

- Spinning reserve

- Ancillary services

- Optimized self-consumption